Bio-inspired structural materials break the dynamic performance tradeoffs

- Zian Jia

- Feb 10, 2019

- 2 min read

Updated: Feb 19, 2019

The use and development of materials are gradually transferring from “available materials” toward “tailored materials” that satisfy multiple performance requirements. However, challenges are faced when tailoring materials to have certain performances – some material properties are mutually exclusive and hard to improve simultaneously, such as that between strength and toughness, compliance and strength, stiffness and dissipation, and fast response and flexibility. These are known as the performance tradeoffs, which must be tackled to get greater freedom and larger design space in “material tailoring”.

In material science, the enhancement of a specific material property is often accompanied by undermining another property, notoriously known as the performance tradeoffs.

While the tradeoff between strength and toughness have drawn the attention of many researchers, the study of fast response vs flexibility, stiffness vs dissipation, and compliance vs strength are rather limited, regardless of recent requirements raised by research areas like wearable devices, flexible armors, reconfigurable metamaterials, and soft robotics. Since the strength and toughness confliction is solved by architected materials with rationally designed microstructures, here, we expand the concept of architected materials to solve the performance tradeoffs between compliance and strength, stiffness and dissipation, and fast response and flexibility. Take a step further, we try to obtain architectures that possess an ideal combination of flexibility, strength, toughness, energy dissipation, and fast response.

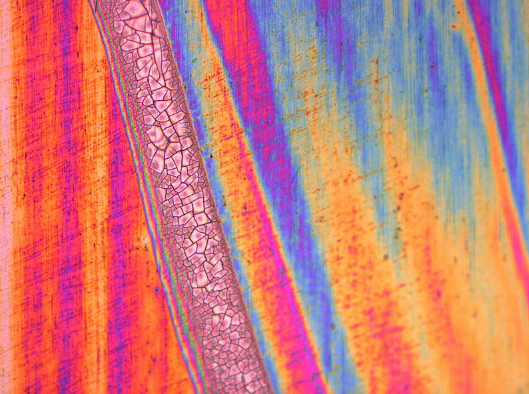

Nature is a master of using material architecture to tailor material functions. Thereby, we follow nature’s motif to create architected materials. With 3D printing and dynamic three-point bending tests, we successfully produced materials that break all the above mentioned tradeoffs. Combining experimental and theoretical analysis, we reveal that the performance enhancements stem from the material architecture’s significant manipulation over the deformation field, crack location, and crack pattern. Along the way, we also show that low order hierarchical design and hybrid design can be combined to improve the material performance while reducing the manufacturing difficulty.

These results are presented in our recent paper published in Materials & Design. The proposed design methodology may found applications in areas like armors, soft robotics, wearable electronics, and metamaterials.

Comments